Los productos de plantilla de pam-xiamen consisten en capas cristalinas de nitruro de galio (gan), nitruro de aluminio (aln), nitruro de aluminio y galio (algan) y nitruro de indio y galio (ingan), que se depositan en sustratos de zafiro. Los productos de plantilla de carburo de silicio o silicon.pam-xiamen permiten tiempos de ciclo de epitaxia 20-7

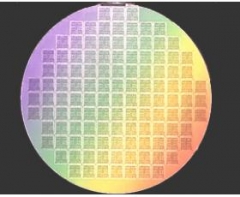

pam-xiamen ha establecido la tecnología de fabricación para la oblea de substrato gan independiente (de nitruro de galio), que es para uhb-led y ld. cultivado por tecnología de epitaxia en fase de vapor de hidruro (hvpe), nuestro sustrato gan tiene baja densidad de defectos.

pwam desarrolla y fabrica sustratos semiconductores compuestos: cristal de arseniuro de galio y wafer.we ha utilizado tecnología avanzada de crecimiento de cristales, congelación de gradiente vertical (vgf) y tecnología de procesamiento de obleas gaas, estableció una línea de producción de crecimiento de cristales, corte, pulido para procesamiento 7

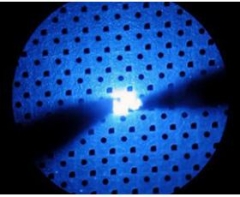

proporcionamos epitaxy sic personalizada de película delgada (carburo de silicio) sobre sustratos de 6h o 4h para el desarrollo de dispositivos de carburo de silicio. sic epi wafer se utiliza principalmente para diodos schottky, transistores de efecto de campo de semiconductores de óxido de metal, transistores de efecto de campo de unión, transisto7

pam-xiamen ofrece obleas de carburo de silicio semiconductoras, 6h sic y 4h sic en diferentes grados de calidad para el investigador y fabricantes de la industria. hemos desarrollado la tecnología de crecimiento de cristal sic y la tecnología de procesamiento de obleas de cristal sic, estableció una línea de producción para el sustrato sic del fabr7

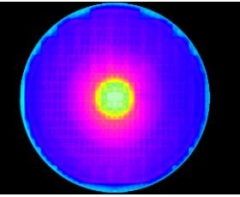

La oblea epitaxial con base en gan (nitruro de galio) de pam-xiamen es para el ultra alto brillo en diodos emisores de luz azul y verde (led) y diodos láser (ld).

Los dobladillos de nitruro de galio (transistores de alta movilidad de electrones) son la próxima generación de tecnología de transistor de potencia rf. Gracias a la tecnología gan, pam-xiamen ahora ofrece algan / gan hemt epi wafer en zafiro o silicio, y algan / gan en plantilla de zafiro .

puede obtener nuestro servicio de tecnología gratuito desde la consulta hasta el servicio posterior basado en nuestro Más de 25 experiencias en la línea de semiconductores.

nuestro objetivo es cumplir con todos sus requisitos, no importa cuán pequeñas sean las órdenes y cuán difíciles son las preguntas pueden ser, para mantener un crecimiento sostenido y rentable para cada cliente a través de nuestros productos calificados y un servicio satisfactorio.

con más que 25 + años experiencias en el campo de material semiconductor compuesto y en el negocio de exportación, nuestro equipo puede asegurarle que podemos entender sus requisitos y tratar su proyecto profesionalmente.

la calidad es nuestra primera prioridad. pam-xiamen ha sido iso9001: 2008 , posee y comparte cuatro modernas facories que pueden proporcionar una amplia gama de productos calificados para satisfacer las diferentes necesidades de nuestros clientes, y cada pedido tiene que ser manejado a través de nue7

Los cristales de poli -si se utilizan principalmente en células solares debido a su bajo costo. Aquí, las zonas de sensibilidad a las longitudes de onda de la luz solar deben expandirse para aumentar la eficiencia de ingeniería de las células solares.. Las películas de semiconductores compuestos del Grupo IV, por ejemplo, películas de Si (Ge) dopadas con átomos de C, Ge (C, Si) y/o Sn con contenidos de varios %, sobre un sustrato de Si o Ge, se han identificado como posibles soluciones a este problema técnico. problema. En este estudio, calculamos la energía de formación de cada configuración atómica de átomos de C, Ge y Sn en Si utilizando la teoría funcional de la densidad. El método "Hakoniwa" propuesto por Kamiyama et al. [Materials Science in Semiconductor Processing, 43, 209 (2016)] a una supercélula de 64 átomos de Si que incluye hasta tres átomos de C, Ge y/o Sn (hasta 4,56 %) para obtener la relación de cada configuración atómica y el valor medio de las bandas prohibidas de Si...

Lee masSe investiga la unión de oblea de GaAs utilizando un tratamiento de sulfuro de amonio (NH4)2S para varias estructuras. Se estudia el efecto del ángulo de corte de la oblea en la conductividad eléctrica de los dispositivos de células solares III-V que utilizan estructuras unidas por oblea n-GaAs/n-GaAs. Se utiliza difracción de rayos X de alta resolución para confirmar la mala orientación de las muestras unidas. Además, comparamos las propiedades eléctricas de las uniones pn crecidas epitaxialmente en GaAs con las estructuras unidas por obleas n-GaAs/p-GaAs. Microscopía electrónica de transmisión de alta resolución (HRTEM) y microscopía electrónica de transmisión de barrido(STEM) se utilizan para comparar la morfología de la interfaz en el rango de desorientaciones relativas después de un RTP de 600 {grados}C. La proporción de regiones cristalinas bien adheridas a inclusiones de óxido amorfo es constante en todas las muestras adheridas, lo que indica que el grado de desorientación no af...

Lee masLa transmisión óptica, la dependencia de la temperatura de la fotoluminiscencia (PL) y la dispersión Raman del SiC poroso preparado a partir de 6H-SiC de tipo p se comparan con los del 6H-SiC de tipo p a granel.. Mientras que el espectro de transmisión del SiC a granel a temperatura ambiente revela un borde relativamente nítido que corresponde a su banda prohibida a 3,03 eV, el borde de transmisión del SiC poroso (PSC) es demasiado ancho para determinar su banda prohibida. Se cree que este borde ancho podría deberse a estados superficiales en PSC. A temperatura ambiente, el PL de PSC es 20 veces más fuerte que el de SiC a granel. El espectro PL PSC es esencialmente independiente de la temperatura. Las intensidades relativas de los picos de dispersión Raman de PSC son en gran medida independientes de la configuración de polarización, en contraste con los de SiC a granel, lo que sugiere que el orden local es bastante aleatorio. Fuente:IOPscience Para obtener más información, ...

Lee masLa transmisión óptica, la dependencia de la temperatura de la fotoluminiscencia (PL) y la dispersión Raman del SiC poroso preparado a partir de 6H-SiC de tipo p se comparan con los del 6H-SiC de tipo p a granel.. Mientras que el espectro de transmisión del SiC a granel a temperatura ambiente revela un borde relativamente nítido que corresponde a su banda prohibida a 3,03 eV, el borde de transmisión del SiC poroso (PSC) es demasiado ancho para determinar su banda prohibida. Se cree que este borde ancho podría deberse a estados superficiales en PSC. A temperatura ambiente, el PL de PSC es 20 veces más fuerte que el de SiC a granel. El espectro PL PSC es esencialmente independiente de la temperatura. Las intensidades relativas de los picos de dispersión Raman de PSC son en gran medida independientes de la configuración de polarización, en contraste con los de SiC a granel, lo que sugiere que el orden local es bastante aleatorio. Fuente:IOPscience Para obtener más información, ...

Lee masEn este artículo se describe un método para recocer un cristal de CdZnTe . Los metales Cd y Zn puros se utilizan como fuentes de recocido, que simultáneamente proporcionan presiones parciales de equilibrio exactas de Cd y Zn para CdZnTe a una temperatura determinada. Las caracterizaciones revelan que la homogeneidad mejora mucho y las densidades de defectos disminuyen en más de un orden y, por lo tanto, las propiedades estructurales, ópticas y eléctricas del cristal de CdZnTe mejoran evidentemente mediante este recocido. La investigación de la dependencia de la temperatura de la calidad de CdZnTe después del recocido muestra que 1073 K es la temperatura de recocido preferible para CdZnTe. Ya se ha demostrado que este proceso de recocido es superior al recocido a presión parcial de equilibrio aproximado mediante el uso de Cd 1− y Zny aleación como fuente de recocido. Fuente:IOPscience Para obtener más información, visite nuestro sitio web: www.semiconductorwafers.net , envíenos un...

Lee masEn este estudio, se transfirió una capa de InP a un sustrato de Sirecubierto con un óxido térmico, a través de un proceso que combina el proceso de corte iónico y el grabado químico selectivo. En comparación con el corte de iones convencional de obleas de InP a granel, este esquema de transferencia de capas no solo aprovecha el corte de iones al guardar los sustratos restantes para su reutilización, sino que también aprovecha el grabado selectivo para mejorar las condiciones de la superficie transferida sin usar la química y mecánica. pulido. Una heteroestructura de InP/InGaAs/InP desarrollada inicialmente por MOCVD se implantó con iones H+. La heteroestructura implantada se unió a una oblea de Si recubierta con una capa térmica de SiO2. Tras el recocido posterior, la estructura unida se exfoliaba en la profundidad alrededor del rango proyectado de hidrógeno ubicado en el sustrato InP. La microscopía de fuerza atómica mostró que después de grabados químicos selectivos en la estructura ...

Lee masRevisamos nuestros esfuerzos recientes en el desarrollo de materiales infrarrojos HgCdSe en GaSbsustratos a través de epitaxia de haz molecular (MBE) para fabricar detectores infrarrojos de próxima generación con características de menor costo de producción y mayor tamaño de formato de matriz de plano focal. Para lograr epicapas de HgCdSe de alta calidad, las capas amortiguadoras de ZnTe se cultivan antes de cultivar HgCdSe, y el estudio de la tensión inadaptada en las capas amortiguadoras de ZnTe muestra que el grosor de la capa amortiguadora de ZnTe debe ser inferior a 300 nm para minimizar la generación de dislocaciones inadaptadas. La composición de aleación/longitud de onda de corte de los materiales de HgCdSe se puede variar en un amplio rango variando la relación de presión equivalente del haz de Se/Cd durante el crecimiento de HgCdSe. La temperatura de crecimiento presenta un impacto significativo en la calidad del material de HgCdSe, y una temperatura de crecimiento más baja c...

Lee masEl grabado húmedo es un paso importante en la fabricación de semiconductores y obleas solares y para la producción de dispositivos MEMS. Si bien ha sido reemplazada por la tecnología de grabado en seco más precisa en la fabricación de dispositivos semiconductores avanzados, sigue desempeñando un papel importante en la fabricación del propio sustrato de silicio. También se utiliza para aliviar la tensión y texturizar la superficie de las obleas solares en gran volumen. Se revisará la tecnología de grabado húmedo de silicio para semiconductores y aplicaciones solares. Impacto en este paso para obleaSe presentarán propiedades y parámetros críticos (planitud, topología y rugosidad superficial para obleas semiconductoras, textura superficial y reflectancia para obleas solares). Se presentará la justificación del uso de una tecnología de grabado y un grabador para aplicaciones específicas en la fabricación de semiconductores y obleas solares. Fuente:IOPscience Para obtener más información, v...

Lee masSe cultivaron películas homoepitaxiales de 4H-SiC en caras porosas de 4H-SiC (0001) fuera del eje de 8° en el rango de temperatura por deposición química de vapor a partir del precursor de bis(trimetilsilil)metano (BTMSM). La energía de activación para el crecimiento fue de 5,6 kcal/mol, lo que indica que el crecimiento de la película está dominado por el mecanismo de difusión limitada. Se incorporaron fallas de apilamiento triangular en la película delgada de SiC desarrollada a baja temperatura de 1280°C debido a la formación del politipo 3C-SiC. Además, las dislocaciones de supertornillo aparecieron seriamente en la película de SiC desarrollada por debajo de 1320°C. Se observó una morfología limpia y sin características en la película de SiC cultivada por debajo de 25 centímetros cúbicos estándar por minuto (sccm) tasa de flujo de gas portador de BTMSM a 1380 ° C, mientras que el politipo 3C-SiC con límites de posicionamiento doble creció a una tasa de flujo de...

Lee masDurante la última década, el uso de capas y estructuras monocristalinas de germanio (Ge) en combinación con sustratos de silicio (Si) ha llevado a un resurgimiento de la investigación de defectos en Ge. En los cristales de Si, los dopantes y las tensiones afectan los parámetros del defecto puntual intrínseco (vacancia V y I autointersticial ) y, por lo tanto, cambian las concentraciones de equilibrio térmico de V e I. Sin embargo, el control de las concentraciones de defectos puntuales intrínsecos aún no se ha realizado al mismo nivel en los cristales de Ge que en los cristales de Si debido a la falta de datos experimentales. En este estudio, hemos utilizado los cálculos de la teoría funcional de la densidad (DFT) para evaluar el efecto de la tensión isotrópica interna/externa ( σin / σ ex ) sobre la entalpía de formación ( H f ) de V e I neutros alrededor del átomo dopante (B, Ga, C, Sn y Sb) en Ge y comparó los resultados con los de Si. Los resultados del análisis son triples. Primer...

Lee masWafer Foundry: 26321#, Liamei Rd. Lianhua Industrial Area, Tong an, Xiamen 361100, China

Información del contacto

Información del contacto luna@powerwaywafer.com

luna@powerwaywafer.com powerwaymaterial@gmail.com

powerwaymaterial@gmail.com  +86-592-5601 404

+86-592-5601 404